Section 6: Feature GuideBar Code Symbologies The printers can automatically print the human readable characters at the bottom of the linear bar code symbols, or they can be left off, as required. The character density of the 2-Dimensional symbologies make it impractical (and self-defeating) to print the human readable characters. Allowable bar code densities are a function of the resolution of the head and are discussed in the section on Resolution. For symbologies that allow you to specify a wide to narrow ratio, the common fixed ratios of 2:1, 3:1 and 5:2 are automatically constructed by the printer. Custom ratios may also be programmed using increments of the dot size.

Code Symbologies Supported Text Fonts

Label Formats

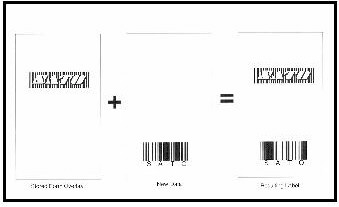

Formats are used to reduce computer transmission time. The typical AJAG label requires approximately 400 bytes of data to be transferred to the printer if it is sent as a complete label. Using a stored format, the label can be transmitted to the printer along with a new serial number with a 21-byte data transfer. In the above example, the memory required to store the format is approximately the same as it takes to transmit the entire label, which is not too bad. However, if we decide to include a graphic logo on the label, the storage requirements can quickly skyrocket. Since there is only a limited amount of memory available for storing formats, a more efficient way is desirable. By storing the image separately, it may be recalled by the printer and printed as an "overlay" on another label. As long as the image size stays the same for all formats, the logo can be simply recalled and printed on any label desired, saving a considerable amount of memory storage. Label Edge Sensing Transmissive or "see-thru" sensing uses a light source positioned on one side of the label with a photo detector on the opposite side. As the label passes between these two, the difference in the light transmission between the opaque label and the liner is used to detect the leading edge of the next label. Liner opacity and uniformity is very critical for proper operation. For tag stock, a notch is cut or a hole punched along one edge, essentially simulating a 100% transmissive liner. Reflective sensing, sometimes called "Eyemark" sensing, is used in conjunction with a non-reflective mark printed on the back of the label liner indicating the start of a new label. The difference in light reflected from the label liner and the mark are used to detect the label edge. This type of sensing requires an additional process step to print the mark on the backside of the label liner or label material. The reflectance background of the liner must be carefully controlled so that enough signal differential is maintained to allow accurate detection of the printed mark. Eye-Mark sensing is most often used with butt-cut tag stock where there is no gap between adjacent labels. SATO printers employ both methods for detection of the edge of the label. They can use either an Eye-mark or see-thru sensing. In addition, they can also use a print line counter when printing on continuous roll paper with a label cutter. Both the see-thru and Eye-mark sensors need to be positioned correctly. The Eye-mark or label gap must pass through the sensor before it can detect the edge. The sensors are positioned along the left side of the label (as seen looking at the front of the printer). It is important that the mark or the label edge be as straight as possible and is perpendicular to the direction of label travel. Otherwise, any variations in label position caused by poorly adjusted label guides will result in variations in the detected edge position. Resolution There are both advantages and disadvantages with this arrangement. The primary advantage is the ease in which precise bar edges can be formed. Also, they do not have to overlap to create a well defined edge. On the other hand, the inability to overlap restricts the bar widths to even multiples of the basic dot size. This restricts the wide/narrow ratios to even multiples, i.e. 2:1 or 3:1, unless multiple dots are used to define the bar width. If the dot is small enough, this is not much of a problem as a 2.5:1 ratio is easily constructed using a 5:2 relationship. However, if the dots are relatively large, a 5:2 relationship results in low density bar codes, which may not be practical for the application. Using the 5 mil and 3.3 mil size of typical thermal transfer label printers, the problem is mostly eliminated since single width bar codes are not recommended except for very special closed loop applications where tight control can be exercised over both the printing and reading of the symbols. The higher resolution printers can also create more aesthetically pleasing human readable fonts and graphic images since the "blocks" used to construct them are smaller. The two main disadvantages of the high resolution printers are related to speed and cost. To maintain a "square" relationship, the distance between print lines should be equal to the width of the dot. Thus, more steps are needed to create a label of the same size. In addition, the larger number of dots requires a larger image buffer. A 4" x 7" label printed at 300 dpi requires a 315 Kbyte buffer while needing only 140 Kbyte at 200 dpi. Unless the image processing time can be decreased, it will take over twice as long to load the image in the print buffer. The high density CL412, CL612 and XL41O alleviate this problem by using high speed 32 bit RISC processors for imaging the label. The increased dpi also means that the print head contains more elements and will be more expensive to replace. The effect of resolution on memory requirements is readily seen by observing the maximum print lengths of a CL608 and a CL612 when a 2MB Memory Card is used. The CL608 can image a label 50" long with the 2MB card while the CL612 can only image a label 32" long. System Options A number of options other than electrical interfaces are offered for the SATO printers, which increase their usefulness in certain applications. The SATO thermal transfer printers can be configured with several options designed to complement their label production capabilities. These include:

(1) User changeable modules. Either Serial or Parallel can be specified at time of order. Copyright � 1998

|

top

Home | The Company | Systems Solutions | Products & Pricing

Software & Support | Reseller Resources | Contact Compsee