Section 4: Label Considerations

Perhaps as important as the type of printer used is

the consideration given to the design and construction of the label

itself. Again, this should be the subject of a specification, especially

if you are expecting someone else to print the label for you. Most

major companies have developed bar code labeling specifications

to which they expect their suppliers to conform. If a shipment is

received without a label or with one that does not meet the specification,

the shipment may be rejected and, worse yet, a fine imposed on the

supplier. A good label specification should, at a minimum, specify

the following information:

- The physical size and construction of the

label.

- The environmental specifications.

- The symbology(s) to be used along with

the technical specifications for the symbol.

- The number, size, position and orientation of the fields along

with the data to be contained in each.

Design

The design of the label is critical. If you are dealing

with a simple item identification label containing nothing but a

single bar code and its human readable information, then it is relatively

simple. However, here you still may be required to make a tradeoff

on whether to print the label horizontally across the label using

a wider web printer or to print it vertically down the length of

the label with a smaller web printer running slower. Complicating

the decision would be the addition of images such as company logos

and fancy human readable printing such as commonly found on retail

bar code tags.

- SIZE

The

physical size of the label must be within reasonable limits. One

too small is difficult for klutzy fingers to position precisely,

while a very large label is almost impossible to apply without

creating a wrinkle (which can destroy the readability of the bar

code). As a general rule, labels as small 1/2' high by 1" long and

as large as 5" high by 7" long can be applied manually without too

much difficulty.

- MULTIPLE BAR CODES

As soon as more than one bar code is included on the label, the

problem of which one is read by the scanner must be addressed.

This can be solved by using different symbologies for each bar

code or by including a "Data Identifier" character at the start

of the data string. The two symbology approach is generally discouraged,

since it requires two symbologies with similar structures and

data encoding capabilities. Another way to separate two different

bar code symbols is to place them at right angles to each other,

but problems appear again when more than two symbols are needed.

Multiple bar code labels must face another problem, that of how

the operator knows which symbol was scanned. This is not difficult

if a hand wand scanner is used, but a moving beam laser operator

has no control over the horizontal scanning of the beam, just

how it is vertically positioned. It is difficult to control which

symbol is being read if they are both placed side by side. In

this case, stacking the symbols vertically, will solve the problem

since the beam can never cut through more than one complete symbol.

All of these problems can be eliminated by use of industry standard

Data Identifiers to identify the data contained in the symbol.

The placement and orientation of the fields

can have a significant effect on the success of a bar code system.

If there is information on the label that must be read by an

operator, then it should be presented in a highly visible area in

a font that will maximize readability. Bar code fields should be

easily identified by the operator who must do the scanning.

- QUIET ZONE

One of the most common mistakes made in label layout is the failure

to Quiet Zones at the beginning and end of the bar code. This

is blank space free of any printing or marks. It is needed by

the decoder to establish the end points of the symbol. While the

decoder may be able to resolve a Quiet Zone that is at least 10

times the smallest bar dimension, the Quiet Zone should never

be less than 0.25". Even at that size, hand scanning with a wand

is difficult because hand motion is very erratic at the beginning

and end of the scan. Placing the bar code too close to the edge

of the label violates the Quiet Zone rule even if the label is

placed on a white surface. The scanner may detect the raised label

edge as a non-reflective bar.

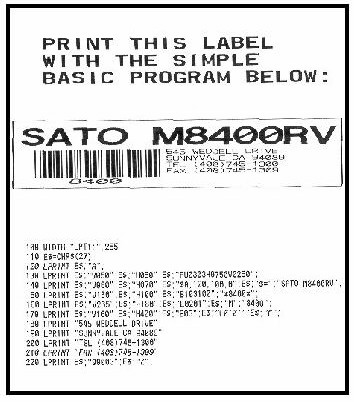

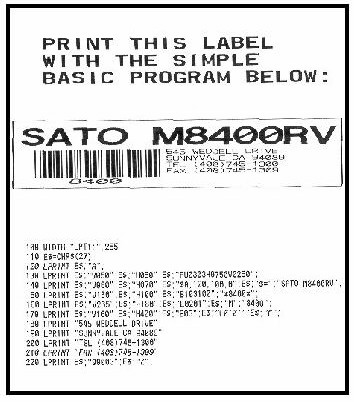

Basic Program and Label

Design Software

After deciding what the label should look like, the

next problem encountered is how to create it. There are two options,

you can either include sufficient write your own program or use

a software package to do it for you. If the number of different

label designs is small, and the data on them is minimal, it is relatively

easy to write a small program to do the job. The Basic program shown

in the illustration will print the example label shown on a SATO

M-8400RV printer. It has only three fields, one a bar code with

HRI information printed below it and two text fields surrounded

by a box. However, the day when the process consisted of sending

a line of characters down to a text printer to be printed upon a

receipt of a carriage return is long gone. Now you have to specify

the font, how large it is, where the characters are to be placed,

the orientation of the field, what type of bar code, etc.

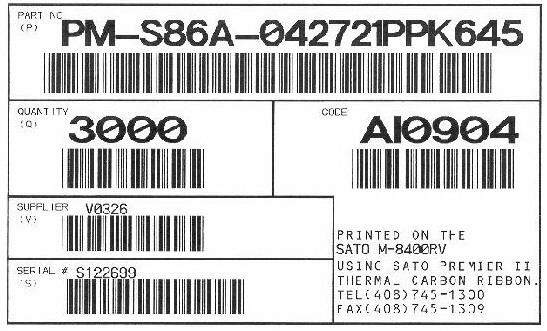

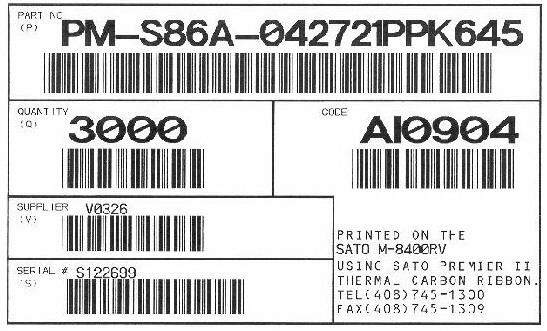

The AIAG shipping label illustrates the problem of

complex label designs. It typically contains 29 fields that must

be separately programmed along with eight border lines. Also, the

information contained in the fields can, and probably will, vary

from label to label. Even if we manage to get all of the fields

programmed correctly, we still have to find a way to easily enter

the variable data into the fields without writing a new program

each time. We are talking serious programming here with "GO TO"

statements, "LOOPS" and other esoteric jargon.

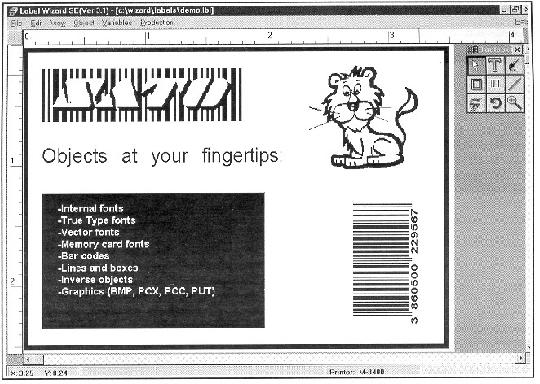

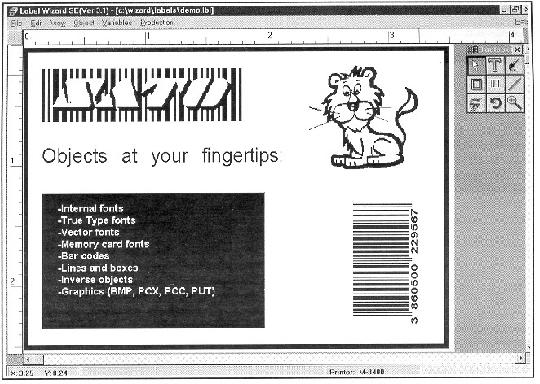

It is obvious that we need something to insulate us

from this process. A label design and software package is in order.

The definition of a "good" label design package depends upon the

label to be designed. For a simple layout, a basic text-based program

asking you to enter coordinates and information with a menu driven

screen is acceptable. However, more complex labels are difficult

to visualize using this method. A WYSIWYG screen layout program

is preferred.

One caveat is in order, even though a label design

program allows you to do all sorts of fancy things, unless the capability

is needed, it can end up complicating your life. The only person

that becomes proficient in using a complicated label design program

is one that uses it a lot. This is not the normal case in the industry,

where it is more likely that a few standard labels will be designed

and used over and over. For this reason, an intuitive design program

is desired, one where you do not spend a lot of time trying to understand

how to use the program. A Windows based program would be a good

choice, since it has a user interface that is familiar to most people.

A Windows design screen from SATO's Label Wizard program illustrates

the advantages. It provides a user-friendly interface that insulates

the user from the intricacies of the design process.

Typical AIAG Shipping Label

A demo copy of Label Wizard can be downloaded free

from the SATO home page on the internet (http://www.satoamerica.com).

This is a complete functional version of the program and contains

all of the features and capabilities of Label Wizard except for

production printing. All of the label formats designed with this

version can be used if a decision is made to upgrade to the full

production version of Label Wizard at a later date.

Printing

Most label design programs will allow you to print labels directly

from the program. Sometimes this is not the way to go. If the operator

only needs to print labels, there is no need to supply access to

the design part of the program. As a matter of fact, it is probably

desirable to limit access since the temptation to "improve" the

design is eliminated. Being able to break the print portion out

into a print only stand-alone program (referred to as a Run Time

program) is the best solution. The operator then has to select the

right label design from a list and identify the source of the data

for the fields.

If the labels are to be used in a production environment,

the ability to automatically access external database files for

the contents of variable fields is a necessity. By defining the

field as a variable and tying it to a database, the information

can be automatically placed in the field at the time of printing.

This allows all database management to be confined to the primary

database and any updates or changes automatically incorporated into

the label without having to modify the label printing job. The database

types can be supported by the program directly or indirectly through

the new Microsoft ODBC (Open Database Connectivity) specification.

- WINDOWS PRINTER DRIVER

Sometimes it is desirable to be able to print

directly to a bar code printer from a standard Windows application

program. To do this you need to load the printer as a standard

Windows printer. A Windows Printer Driver is available for many of

the more popular bar code printers. Windows drivers for SATO

printers are available free of charge from SATO. These drivers

support all of the bar code symbologies resident in the SATO

printers. This allows precise control of the bar code to ensure

that it is printed within specifications.

- USING TrueType� BAR CODE FONTS

Bar codes can be printed from standard Windows applications using

bar code TrueType� fonts, of which a number are available from

different sources. These can be used successfully with the SATO

Windows Printer Driver, but extreme care must be used to ensure

that readable bar codes are printed. There are several areas in

which careful attention must be made:

- Type Size - By design, TrueType� fonts

are scalable fonts. You specify a type size and the computer

generates the best fit using the resolution of the printer. This

works great for human readable fonts, but can cause problems

with bar code fonts. For example, the TrueType� expansion

algorithm tries to make the font outline smooth and decides when

an element is printed with one dot versus going to the next size

by adding another dot. When printing bar code fonts, this can

cause variations in the relative bar widths, resulting in an

unreadable bar code. TrueType bar code fonts are designed to be

printed at specific type sizes using a certain resolution

printer. Using a different type size or a different resolution

printer can destroy the critical bar width relationship of the

bar code.

- Start/Stop and Check Digit Characters

-When data is input for TrueType� fonts, any necessary

start/stop or check digit characters must be included.

- Data Input - Some bar codes support a

number of character sets, many of which are not present on a

typical PC keyboard. The TrueType font must assign some key

combination for these characters.

- Graphics - All TrueType text information is sent in a graphics

format, including bar code symbols. This greatly increases

the transmission time required for each label.

Label Wizard Windows Design Screen

Copyright � 1998

Sato America, Inc.

Return

to Media Index

|