Section 2: Selecting A Print Technology

All of the major print technologies have some advantages

and disadvantages when used in a demand label application. It is

possible to make a particular technology fit the application, but

this generally involves compromises that may not make sense. It

is more practical to select a printer based on a set of reasonable

tradeoffs. For instance, a label printer is not often used for printing

text documents, so this capability should not be included in the

primary selection criteria.

Before requirements can be matched to a particular

type of printer, something must be known about the different characteristics

of the technology and what they mean to bar code printing. Most

of the familiar print technologies were developed for producing

human readable text information. They can be modified to print bar

codes, but what makes a good text printer does not necessarily make

a good bar code printer. The more successful bar code printers have

been optimized for this purpose. An example of optimization for

bar code printing is the shape of the print dot used by matrix printers.

A square or rectangular dot makes a bar with a very defined edge,

something scanners like to see. A round dot produces a bar with

a scalloped edge, harder for the bar code scanner to read, but it

makes a human readable character that is more pleasing to the eye

than the harsh corners of the square dot. Square dots make better

bar codes while round dots are better suited for text documents.

Another differentiation is the size of the print field. Text printers

are designed to print document size pages, while label printers

limit themselves to practical label sizes.

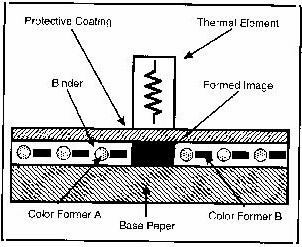

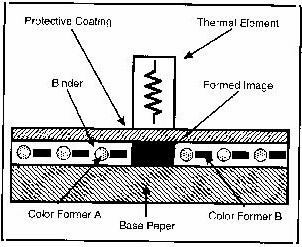

Direct Thermal

Direct thermal printing has more of a public image

problem than a performance problem. While it is sensitive to heat

and ultraviolet light, the degree is much less than most people

suppose. It does offer one unique advantage not available in any

other of the technologies presented here. It does not depend upon

a secondary substance transfer to generate a mark on the paper.

Direct thermal printing chemically alters a coating to produce the

desired image. There is no secondary ink substance that must be

disassociated from a carrier and made to adhere to the label surface.

If the thermally active layer is covered by a protective coating,

as all thermal printer manufacturers recommend, the image is shielded

from surface abuse and contamination. The only thing that can get

to it without first having to break down the protective layer is

radiated energy in the form of either heat or ultraviolet light.

Foreign contaminates or surface abuse must first destroy the protective

coating before affecting the image.

Thermal Printing

� ADVANTAGES

- Quality -

Because of the square image elements and the non-reliance on a

secondary substance transfer, direct thermal labels produce high

quality bar codes with excellent bar edge definition. � Simplicity

- The absence of any ribbon/toner mechanisms makes the direct

thermal mechanism inherently simple. This results in a less

complex media loading path for more user friendly consumables

handling.

- Resolution -

The thermal print elements can produce a consistent dot pattern

down to 5.0 mils (200 dpi) when printing in a horizontal mode

(parallel to the paper movement). This allows ultra high density

bar code printing. When printing in a vertical mode however, the

speed must be reduced significantly to allow the elements to cool

down before stepping to the next print position. While it is

possible to print bars down to 5.0 mils when the print speed,

paper sensitivity and power applied to the elements are carefully

matched, it is best to avoid printing narrow dimensions of less

than 10 mils in the horizontal mode and 15 mils in the vertical

mode.

- Cost - The elimination of any ribbon/toner mechanism

results in a lower initial printer cost. It also results in a

more favorable consumable cost when compared to either thermal

transfer or laser printers.

� LIMITATIONS

- Environment -

The two most severe environmental limitations are exposure to high

temperatures or prolonged exposure to direct sunlight. The

development of new thermal papers has pushed the upper temperature

range upward to about 2120F and special ultraviolet filter

coatings can be applied that will extend the exposure time to

sunlight from weeks to months and will retain an acceptable

quality image for most purposes.

- Spectral Response - The bars created by the standard thermal dyes used

in the label coatings are relatively transparent to infrared

light, limiting the usefulness of standard label media to visible

light scanners. Special label coatings are available that work

with both visible and infrared light sources, but also increase

the cost of the label. If it is to be read by both types of

scanners, then the infrared stock should be specified.

- Media - The thermal paper used must match the characteristics

for which the printer was designed. Because of the various "speeds"

(sensitivity to heat) available in thermal papers, not all printer

and paper combinations are compatible. When properly matched however,

they will yield excellent quality bar code symbols.

SATO M-5900 Thermal Printer

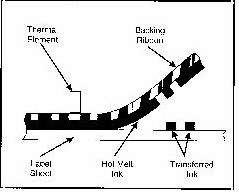

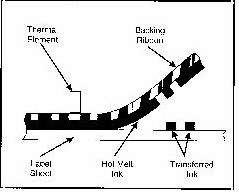

Thermal Transfer

Thermal transfer printing is basically a direct thermal

process that has a ribbon interposed between the head and the label.

The heat from the print head is used to release the ink from a mylar

ribbon and make it adhere to the label surface. Since this type

of thermal process now relies upon a secondary substance transfer,

some of the advantages of direct thermal are lost, but heat restrictions

have been improved and sensitivity to ultraviolet light has been

eliminated.

� ADVANTAGES

- Quality - The

ink transferred to the label surface produces excellent bars with

quite high contrast ratios which are very stable and resist

deterioration. The use of square print dot elements also gives

excellent bar edge quality.

- Resolution -

The thermal print elements can produce a consistent dot pattern

down to 3.3 mils (300 dpi) when printing in a horizontal mode

(parallel to the paper movement), allowing ultra high density bar

code printing. When printing in a vertical mode however, the speed

must be reduced significantly to allow the elements to cool down

before stepping to the next print position. While it is possible

to print bars down to 5.0 mils when the print speed, paper, ribbon

and power applied to the elements are carefully matched, it is

best to avoid printing bar codes with a narrow dimension of less

than 10 mils in the horizontal mode and 15 mils in the vertical

mode.

- Speed -

Because it takes less energy to release the ink from the ribbon

than it does to develop a dot using thermally sensitive paper, the

print speed of thermal transfer printers is faster than their

direct thermal cousins. With the same print head and mechanism, it

is typically twice as fast when printing comparable images in the

direct thermal mode.

- Dual Mode Printing - Since the thermal transfer printer is essentially a

thermal mechanism with a ribbon positioned between the head and

the paper, it can also be used to print in a direct thermal mode

if the ribbon is not used. However, the head life will be

considerably reduced because it is no longer protected by the

ribbon.

- Media Selection - Bar code symbols can be generated using

a wider range of paper and vinyl substrates that are more resistive

to heat, water and light than in the direct thermal process. By

proper selection of the label material and the ribbon, a very

strong bond may be obtained between the ink and the label surface,

giving performance comparable to direct thermal labels with protective

surface laminations.

� LIMITATIONS

- Ribbons - The

ribbons are single pass and the printing of a single dot in a row

wastes the remaining ink on that row. This results in a very high

ribbon usage and associated cost. The ribbons are a thin mylar or

similar material coated with ink on one side and can be difficult

to handle, especially if they are very wide.

- Label Cost -

Because of the high ribbon usage, usually on the order of one

ribbon roll for each two rolls of labels, the cost of labels is

higher than with most of the other common technologies.

- Ribbon/Media Compatibility - The adherence of the ink

to the surface is the source of most of the durability problems

with thermal transfer images. If improper ribbon formulations

are used, the transferred ink may flake at the edges when contact

scanners are used, or become smudged from oily finger prints.

Thermal Transfer Printing

Press Printing

This category encompasses all of the press technology

available for off-site printing. This includes film masters, flexography,

offset lithography, gravure, letterset, hot stamping and many others.

It offers the widest range of quality labels available for bar code

printing. The most important step for procuring off-site printed

labels is the generation of a good specification for the label,

detailing the precise dimensions of the symbols and media upon which

they are to be printed. Selection of a label vendor should be based

primarily upon their experience and reputation. This probably won't

be the lowest cost bidder, but will most likely represent the lowest

overall cost if headaches and mistakes are taken into consideration.

� ADVANTAGES

- Label Material Selection - Because of the many print processes available for

use, the range of materials available on which bar codes may be

printed is almost limitless. Special materials are available for

high temperatures, and even metal plates can be imprinted with bar

coded information.

- Cost - If a

large quantity of identical labels are required and they do not

have any special requirements to drive up the price, cost per

label will be relatively inexpensive.

- Quality -

High quality should be expected for press printed labels. While it

is possible to get low quality labels using off-site vendors, the

cause can usually be traced to poor workmanship or a lack of

understanding of the bar code symbol requirements. Excellent

quality labels that survive under harsh conditions can be obtained

by the selection of the correct print process and base label

material.

- Label Size - The printable label size is limited only

by the dimensions of the press web, which can be very large.

� LIMITATIONS

- Variable Data

- It is difficult to print labels where each one must contain

different data. Even sequential numbering using bar code symbols

is a task. It involves not just the changing of a single

character, but the rearrangement of a series of bars and spaces.

- Advance Data

- The data for the label(s) to be printed must be known far enough

in advance to allow for the preparation of the print masters and

scheduling of press time. If special labels are needed, extra time

must be allowed to obtain any non-standard materials.

- Cost - If only a small number of labels are needed, the cost

per label can be high, reflecting set-up charges that are now

prorated over fewer labels.

Solid Font Impact

Solid font impact printers come the closest to typewriters

in technology and limitations. They print the bar codes by constructing

the symbols with preformed bars or by printing the complete character

with a single hammer blow. The constructed code method must be used

if the symbol to be printed represents a large area per hammer blow,

or if a continuous code is chosen.

� ADVANTAGES

- Simple Interfacing - Send the printer a character code and that is

what it prints. No worrying about aspect ratios, different code

symbologies, etc.

- Quality - Since each bar is precisely formed, the edge

definition is excellent and good quality bar code symbols are

produced.

� LIMITATIONS

- Fixed Format

- Since each bar or symbol is preformed, the label format,

symbology codes or character densities cannot be changed without

changing the code wheel. Alpha characters may be printed, but are

restricted to a particular location determined by their position

on the code wheel. All symbols must be printed in the same

orientation, and orthogonally (i.e. at right angles) printed

symbols cannot be produced.

- Speed - Each

bar or symbol is located sequentially on the code wheel and the

print speed is limited by the rotational speed of the wheel.

- Mechanical -

The operation of the mechanism depends upon numerous moving parts

with large masses. The hammer blows and code wheel rotation must

be properly synchronized or smearing will result.

- Symbol Area - If small area symbols are printed, there

is a tendency for "ticking" to occur. This is ink transfer in

areas between characters or on edge of adjacent characters.

Impact Dot Matrix

Dot matrix printers are very popular in the computer

industry for document printing. Many have been pressed into bar

code service because they are cheap and everyone with a computer

probably already has one. However, the ones best suited for bar

code applications are the line printer types, the ones that are

not cheap and only used in limited computer applications. The most

effective dot matrix printers generally have additional intelligence

in the form of a graphics controller card to reduce transmission

time for complex labels.

� ADVANTAGES

- Versatility -

Dot matrix printers are one of the most versatile types available.

They can print bar code symbols or text documents in any

orientation and with various height and width symbols. They are

especially adept at printing multi-copy forms that include bar

code symbols for document tracking and control. When printing bar

codes on multi-copy forms however, the top copy will be the only

one readable by a scanner.

- Equipment Cost - Dot matrix printers are used in large

quantities by the computer industry and the initial cost of the

equipment is low. However, care should be exercised in selecting

a dot matrix printer for bar code applications on the basis of

price or availability. Also make sure it can print suitable quality

symbols.

� LIMITATIONS

- Carriage Width - Most of the common dot matrix printers were designed

primarily for printing documents. The width of the carriage is

determined by the smallest sheet size (usually 8.5 x 11'). Bar

code labels tend to be much smaller and have to be printed

"multiple up" to take advantage of the print speed. Also, if the

printer uses the standard puller tractor arrangement, the label

must clear the tractor assembly before it is easily accessible.

Fitting a label stripper or cutter to such a printer presents some

mechanical challenges.

- Quality -

When used to print bar code symbols, dot matrix printers have

several factors going against them. First, the edge definition of

the bar is poor and overlapping dots must be used to meet the

specifications. When overprinting to increase the bar density and

fill in the ragged edges, new ribbons will bleed excessively at

the bar edge causing bars to be too wide and the adjacent spaces

too narrow, while worn ribbons not containing enough ink will tend

to print the bars will too narrow with adjacent spaces being too

wide. Second, irregular paper spacing will cause problems with

vertically printed symbols. If the printer uses a serially driven

head, then irregular head motion will result in problems with

horizontally printed symbols.

- Spectral Response - The standard ink in a dot matrix printer ribbon is

not readable to scanners using infrared light. Carbon must be

added to make it infrared scannable, but carbon will cause the

print head to wear out prematurely. Special mylar ribbons using

carbon have been developed to overcome this problem, but most are

single pass and have a very limited lifetime. The dry carbon

transferred from the mylar ribbons must adhere to the surface

since it is not absorbed by the label material.

- Resolution - The best resolution offered by dot matrix

printers comes from the 24 pin print heads that use 8 mil diameter

print wires. When ink bleed is taken into consideration, the dot

size will end up between 9 and 10 mils, giving a medium density

bar code symbol at best. When printing low density symbols such

as those called for by the AIAG B-3 Shipping Label, the 8 mil

wire requires several overlapping dot rows to print the proper

bar width. Conversely, printers using nine pin heads with 12 mil

print wires can create the symbol more easily, but are limited

to printing only low density bar codes.

Laser

The term laser is used here to refer to any printer

using a xerographic or similar type of printing process. Liquid

Crystal Shutter (LCS) arrays, Light Emitting Diode (LED) arrays

or lasers are used to expose the surface of the image drum, with

the laser being the most popular. These printers are invariably

page printers and are not well suited for demand label applications.

They are most commonly sheet fed printers, but some of the newer

laser printers designed for bar code applications employ a tractor

feed system whereby continuous forms may be used.

� ADVANTAGES

- Aesthetics -

Laser printers commonly have a resolution of at least 300 dots per

inch, with some of the newer models being capable of printing at

600 or 1200 dpi. This allows them to print almost typeset quality

characters and high resolution graphic images. These can be

combined with bar code symbols on a label to produce very nice

looking labels with complicated designs.

- Resolution -

At 300 dots per inch resolution (a 3.3 mil dot size), laser

printers can create ultra high density bar code symbols. However,

it is not generally recommended that bars be printed less than 6.6

mils (two dots wide on a 300 dpi printer) unless the symbol is to

be scanned in closed loop applications where the scanning

equipment used can be controlled.

- Multi-Application - Lasers are the printers of choice

for documents where bar code symbols and quality document printing

must be intermixed.

� LIMITATIONS

- Page Printer

- Since laser printers are basically page printers, it takes as

much time and media to print a single small label as it does a

large label. If it prints at six pages per minute, it takes 10

seconds to print a whole page or a single bar code symbol. Some of

the newer laser printers designed for bar code applications have a

variable page length feature, but the physical distance between

the imaging drum and the fusing roller prevents an image from

being placed immediately following the previous image. They are

therefore poor choices for typical demand label applications.

- Heat - Laser

printers use heat to fuse the toner to the surface of the paper, a

lot of heat. The adhesive coating on the back of a label tends to

seep out between the die cut edges when heat is applied. In ion

deposition printers, the heat is replaced by pressure, but the

result can be the same. Special adhesives must be specified for

these printers.

- Label Imaging Time - Because of the large number of dots

per inch, the time required to image a label can be substantial.

Compounding the problem is the requirement for a complete page

to be imaged even if it consists of a number of identical smaller

labels.

Ink Jet

Ink jet printing has several drawbacks when used

for printing bar code symbols, but does find some use in specialized

applications. The main problems with bar code printing are involved

with the formation and control of the dot. Since the ink is absorbed,

the paper porosity, ink viscosity and drying time must be carefully

controlled. The most pronounced symbol quality problems are associated

with the edge definition, contrast ratio and consistent bar widths.

Some of the new ink jet techniques use a solid ink that is liquefied

with heat and placed on the paper where it reverts to its solid

state. This gives better edge definition and contrast ratios but

leaves a raised print image which can cause problems with contact

scanners. Special ink jet systems have been developed to print low

resolution bar codes directly on corrugated surfaces. Using independently

mounted nozzles, the images are formed as the container is moved

by on a conveyor system.

� ADVANTAGES

- Non-contact - The primary advantages of ink-jet printing

is that it is a non-contact printing technology. This removes

any wear on the head due to contact abrasion. This also allows

surfaces with irregular finishes to be printed if they are compatible

with the ink.

� LIMITATIONS

- Media Surface

- The ink must be absorbed into the surface of the media,

requiring a controlled surface porosity and finish. Because bar

codes involve much higher printing densities than text, the media

requires a longer period of time to dry sufficiently before it can

be handled without smearing.

- Ink Formulation - The ink must dry quickly, but not in the nozzle.

The compromise between these two extremes requires the head to be

purged or cleaned between print jobs. Water based inks are also

very susceptible to exposure to moisture. A single drop of water

can render a bar code unreadable.

- Infrared Response - If infrared scanners are used, carbon

or some other infrared absorbing material must be added to the

ink. This can cause excessive wear on the ink nozzles.

Matching Technology and Requirements

The selection of the proper technology for generating

bar coded labels is a very complex process. It involves not only

an understanding of the print technology to be used, but the label

usage requirements as well. These two bodies of knowledge must be

combined in the selection process to ensure that the bar code labels

produced will give satisfactory performance for their required lifetime.

Some of the factors to be considered are:

- What are the environmental requirements?

- What is the total cost target per label?

- Does the data content change?

- How will the label be scanned?

- How will the label be applied?

- How often will a label be required i.e., (10 labels per second,

etc)?

Copyright � 1998

Sato America, Inc.

Return

to Media Index

|