Wireless Services Pictorial(Click on any image for a full-size view) Access Point In Compsee Enclosure

For optimum reception, the two omni-directional antennas are positioned at maximum distance from each other via horizontal pipes anchored to the enclosure. The dual-antenna arrangement helps reception performance as, due to battery considerations, Symbol�s portable wireless terminals are designed to transmit only at 1/5 of the output power of an Access Point. Each Access Points transmits on one antenna port but receives via two antenna ports. As shown, electrical wiring and ethernet cabling are neatly contained in bright orange polyvinyl conduits for protection and visibility. Compsee can handle all tasks related to installation of an entire wireless backbone. Our staff technicians are fully trained and licensed to run and install Ethernet, fiber optic and electrical cabling. In addition to installation services, Project Management is a highly recommended service offered by Compsee to guarantee success in implementing an wireless solution. Our staff can oversee every aspect of the project, from site survey through installation and testing. We always work closely with our customers with logistics and scheduling to ensure minimal interruption of their operations during installation.

Access Point Environmental Enclosure

Compsee also offers a high-temperature enclosure model with a built-in fan module. This version is useful for use in environments where ambient temperatures can be in excess of 120 degrees Fahrenheit. A stainless steel version is available for use in chemically corrosive environments. For fiber optic applications, a special model is available which includes a media converter and a fan module to dissipate the extra heat generated by the media converter. We can design and fabricate most custom hardware required for a total turnkey solution. Our engineering design group and our manufacturing facility are based at our corporate headquarters in Mt Gilead, NC.

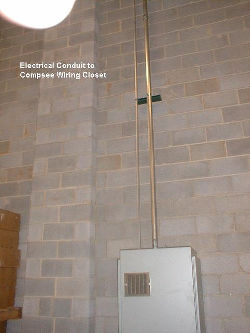

Wiring Closet Compsee can design and fabricate most custom hardware required for a total turnkey solution. The wiring closet shown was designed by Compsee from the ground up and fabricated at our manufacturing facility in Mt Gilead, NC. Compsee�s wiring closets typically serve as hubs to interface Ethernet, electrical and fiber optic cabling, as well as control centers for electrical power. Compsee�s wiring closets can also be designed to serve as "nerve centers" for analyzing data traffic and/or perform network diagnosis, all in real time. This function requires the use of special software tools such as Symbol�s Wavelink SNC24. For example, if a single Access Point were to malfunction, traditional diagnosis methods required for a technician to manually visit each Access Point location one by one and test each hardware unit for functionality. This can be an extremely time-consuming task. It can also be hazardous (especially in a busy warehouse or distribution center environment) as Access Points are typically mounted high on ceilings and rafters. With Compsee�s wiring closet, a technician can instantly view the entire wireless LAN infrastructure and, within minutes, identify the faulty Access Point as well as the cause for the failure. If necessary, the technician can then use the wiring closet to safely and effectively reload firmware onto the faulty Access Point, reboot it, etc.

Electrical Conduit

Compsee can handle all tasks related to installation of an entire

wireless backbone. Our staff technicians are fully trained and licensed

to run and install Ethernet, fiber optic and electrical cabling.

Vehicle Radio Computer

Correctly installing vehicle-mounted wireless terminals on forklifts can be technically challenging due to typically extreme operating conditions. For example, repeated stop-go can result in voltage spikes and inconsistent electrical delivery, thus requiring careful selection of a unique combination of power converters and dampers. Furthermore, excessive vibration may require special harnessing and insulation techniques to ensure long-term, trouble-free operation. Operator preferences can also affect mounting and installation methods. Compsee has installed over 150 units on many different types of forklift models. Why take a chance? When experience and knowledge counts, you can depend on us.

Wall Marking Compsee occasionally receives unique requests from customers, and we always so whatever we can to help. In a recent project, we were asked to permanently embed barcode labels on wall sections. Although seemingly a relatively simple task, wall labeling can require a inordinate amount of technique, technology and prerequisite knowledge. For example, the type of adhesive selected must correspond to temperatures experienced by the wall as well as by the surrounding environment. Our technicians were once called under emergency to correct an installation performed by a competitor; cold overnight temperatures had caused the vast majority of labels to fall off and the warehouse was literally forced to shut down until the problem was resolved. This unfortunately (but expectedly) resulted in revenue loss and disarray in operations. Compsee�s wealth of knowledge, acquired through training and experience, assures our customers that the job will be done right the first time, all the time.

Floor Marking

Although seemingly a relatively simple task, floor labeling can require a fair amount of technique, technology and prerequisite knowledge. For example, the type of adhesive and coating selected must correspond to floor temperatures as well as the severity of the physical environment (such as punishment from heavy forklifts or sandy surroundings). For added durability, the clear sealant must be applied with heat treatment techniques. Compsee�s wealth of such knowledge, acquired through training and years of experience, assures our customers that the job will be done right the first time, all the time.

Reference Accounts

Combined experience of our engineers and technicians total over 90 years. All Compsee engineers, technicians, salespersons and marketing staff are Wireless-Certified by Symbol Technologies. In fact, we were the very first Symbol partner to acquire wireless certification in Symbol�s Spectrum 24Ò wireless LAN system. Our partnerships with established middleware and Warehouse Management Systems providers affirms our ability to deliver a total solution anytime, anywhere in the nation. |

top

Home |

The Company | Systems

Solutions | Products

& Pricing

Software &

Support | Reseller

Resources | Contact

Compsee