COMPSEE Application Stories

COMPSEE Application Stories

Chattem Turns Bar Code Compliance

to Internal Advantage

An RF-based picking and order verification system pays dividends.

Chattem, Inc. is a manufacturer and distributor of health and beauty aids and over-the-counter drugs with annual sales approaching $125 million. Headquartered in Chattanooga, Tennessee, the company supports a manufacturing and distribution center in Chattanooga, and ancillary facilities in strategic locations throughout the world. Initially, Chattem needed an order verification and bar code labeling system to meet Wal-Mart and Kmart guidelines.

Chattem, Inc. is a manufacturer and distributor of health and beauty aids and over-the-counter drugs with annual sales approaching $125 million. Headquartered in Chattanooga, Tennessee, the company supports a manufacturing and distribution center in Chattanooga, and ancillary facilities in strategic locations throughout the world. Initially, Chattem needed an order verification and bar code labeling system to meet Wal-Mart and Kmart guidelines.

The company processes 500 to 800 orders daily at their 100,000-square-foot distribution center. Product lines include FLEX-ALL 454 (the topical analgesic promoted by Joe Namath), Cornsilk Cosmetics, Bull Frog Waterproof Sun-Block, Pamprin, Phisoderm, and Gold Bond Powder among other products.

The company was using printed pick lists and a manual stencil system to assemble and label pallets of product shipped to customers by common carrier and UPS. "The stencils weren't always legible causing some misshipments," according to Gerry Wall, MIS Director. "We had more inconsistencies and lack of control than we were able to identify without automation."

"We contacted several vendors when we started," said Mr. Wall. "After carefully reviewing the references of a number of companies, we selected Barcom, Inc. here in Chattanooga because they offered local support, attractive pricing, and they exhibited in-depth knowledge in an area that was new to us. They were very careful to define the project completely before beginning implementation, and they've been a true partner ever

since, providing regular training and quality support."

"We contacted several vendors when we started," said Mr. Wall. "After carefully reviewing the references of a number of companies, we selected Barcom, Inc. here in Chattanooga because they offered local support, attractive pricing, and they exhibited in-depth knowledge in an area that was new to us. They were very careful to define the project completely before beginning implementation, and they've been a true partner ever

since, providing regular training and quality support."

Jim Ledbetter is President of Barcom, Inc., a bar code systems integrator in business for six years in Chattanooga. Barcom is a value-added reseller for Compsee, Inc. (Mt. Gilead, North Carolina).

"We established our initial contact with Chattem through telemarketing," Ledbetter said. "At that time they were putting bar code on product and shipping cases -- strictly customer compliance for Wal-Mart, Kmart, and other retail accounts. They were looking to use bar code technology internally. We did a pilot project for customer returns, scanning product and case codes in order to log returned product back into their finished-product inventory, on their Novell network. After that successful pilot, we went into the distribution center."

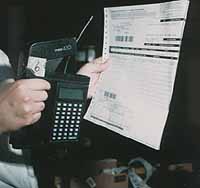

Barcom recommended Mars MEQ 430 terminal/scanners, Monicor's narrowband RF base station, and RJS 260 and Datamax Prodigy Plus thermal transfer printers all supplied by Compsee, for the hardware side of the order verification system. Barcom wrote the system code and oversaw the implementation.

"The MEQ scanners are extremely durable and can withstand being dropped or even run over in the warehouse," commented Gerry Wall, of Chattem. "The Monicor base station was very reasonably priced, integrated easily with our Novell network and has performed flawlessly, even after being relocated to a separate room within the facility."

DC Order Verification

EDI orders are received by the company's IBM 4300, the company's business systems platform located in the main office. The orders are downloaded to the distribution center's 10-station Novell network. Shipping orders are printed on a Genicom dot matrix printer in the DC, which serve as a combination pick list, bill of lading, and packing list. Pickers take their assigned shipping orders/pick lists and scan the Interleaved 2 of 5 case code, and the lot number (an internal Code 128 affixed to the pallet of product brought to the pick area from manufacturing). The picker then enters the quantity, and scans the shipping order number from the paper shipping order/pick list. The system verifies the correct product has been picked or notes exceptions. Picked product goes on a forklift-mounted blank pallet, which will ultimately go to shipping.According to Jim Ledbetter of Barcom, once the items are picked, the picker closes the order via a command on the MEQ scanner, and the system checks for short orders. When the order is verified, then the pallet continues to a third and final check. The pallet goes on an in-line scale, where actual weight is compared to standard product weights resident in the system. If the actual weight is outside tolerance, the system stops the process and ask for a validation.

"Then we print the UCC Code 128 shipping label," Gerry Wall explained. "The shipping label encodes such data as order number and SKU number, along with customer information from the original EDI order or manually-entered orders. After labeling, the shipment is staged on the loading dock. We print out a bar coded serial number [no relation to the serial number on the shipping label] on a carrier confirmation. When the driver signs it, it's scanned into the system at the shipping office, with a tethered PSC laser scanner supplied by Compsee." ASN generation and updating of inventory complete the process.

The Novell network periodically updates the IBM 4300 to provide real-time access to order status by both Chattem's sales personnel and customers (via dial-up connection).

Benefits

Chattem's Gerry Wall said, "This system actually paid for itself before it was ever used to meet the actual need it was purchased to fill. Because we realized that the system would prove beneficial to all customers, we elected to use it for all of our shipments. The system essentially provided savings from increased shipment efficiency and accuracy before Kmart and Wal-Mart were ready for us to go on-line. We were able to eliminate two full time pickers and significantly reduced our requirement for temporary seasonal workers.""Basically," Gerry Wall concluded, "we can handle greater volume with less staff. We recently added Gold Bond to our product line, which is the largest acquisition we've made in terms of volume. We haven't added anybody or additional scanners to the picking operation, nor has it affected our shipping accuracy or schedules."

Jim Ledbetter added, "We started the project because Kmart and Wal-Mart required it, but we went ahead and took advantage of the other benefits. Picking accuracy went sky-high. It also increased picking productivity and also lot traceability through scanning pallet lot labels. As for reliability, the Compsee supplied Mars MEQ/Monicor RF scanner hardware are like a rock. They've now been in service for most of five years in a rough environment. In that length of time we've had three, tops, in for repair. That's phenomenal for that type of environment," Ledbetter said.

Today, Chattem ranks in the top five percent of Wal-Mart suppliers in both accuracy and on-time delivery. The company reports that only two shipping errors occurred during all of 1995. In addition, the system is seeing service in the receiving area. Plans are underway to apply the system to additional DC applications, such as location tracking. Chattem anticipates more savings after it combines the (currently separate) UPS and Common Carrier lines into a single operation.

| Application Profile | Automated order verification and lot tracking system |

|---|---|

| Benefits | Increased shipping accuracy, picker productivity, lot traceability, customer service |

Reprinted from:

-

Business Systems Magazine

Corry Publishing, Inc.

October 1996

© 1998 Compsee, Inc. All Rights Reserved. Please read our disclaimer.

Back to COMPSEE Application Stories

COMPSEE Home

| Corporate Profile

| Systems Solutions Group

| What's New

| Calendar

Products Specifications

| Product Pricing

| Application Stories

| Download Shareware

Contact Us...

| Information Requests

| Email Us